Design and development in a metal casting company involve creating and testing molds and casting methods to produce components that meet technical specifications and customer needs. The company often performs material and process analysis to ensure that mold designs can be produced efficiently and meet strict quality standards. During the development phase, metal component prototypes are thoroughly tested to ensure strength, durability, and dimensional accuracy before commencing mass production.

DESIGN

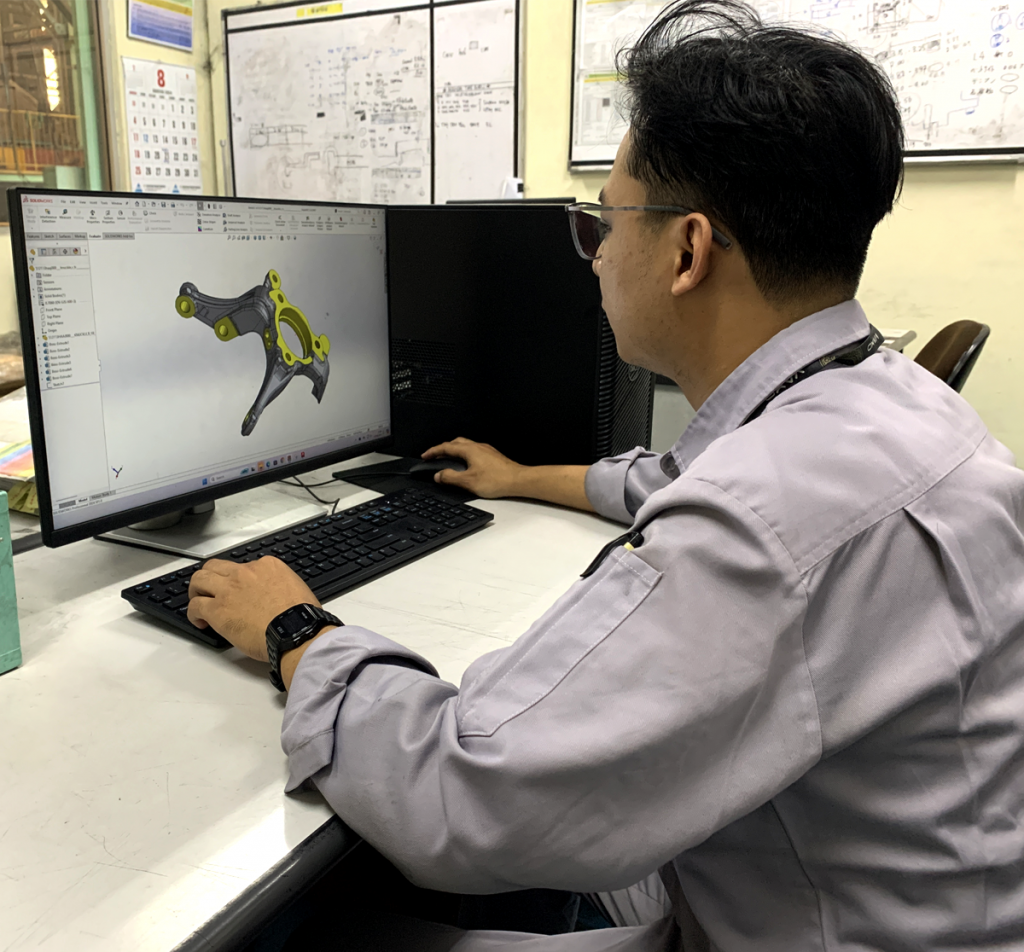

3D design for products using SolidWorks involves creating a digital model that accurately represents the shape and features of the object. SolidWorks allows designers to produce realistic visualizations and perform in-depth analysis before production.

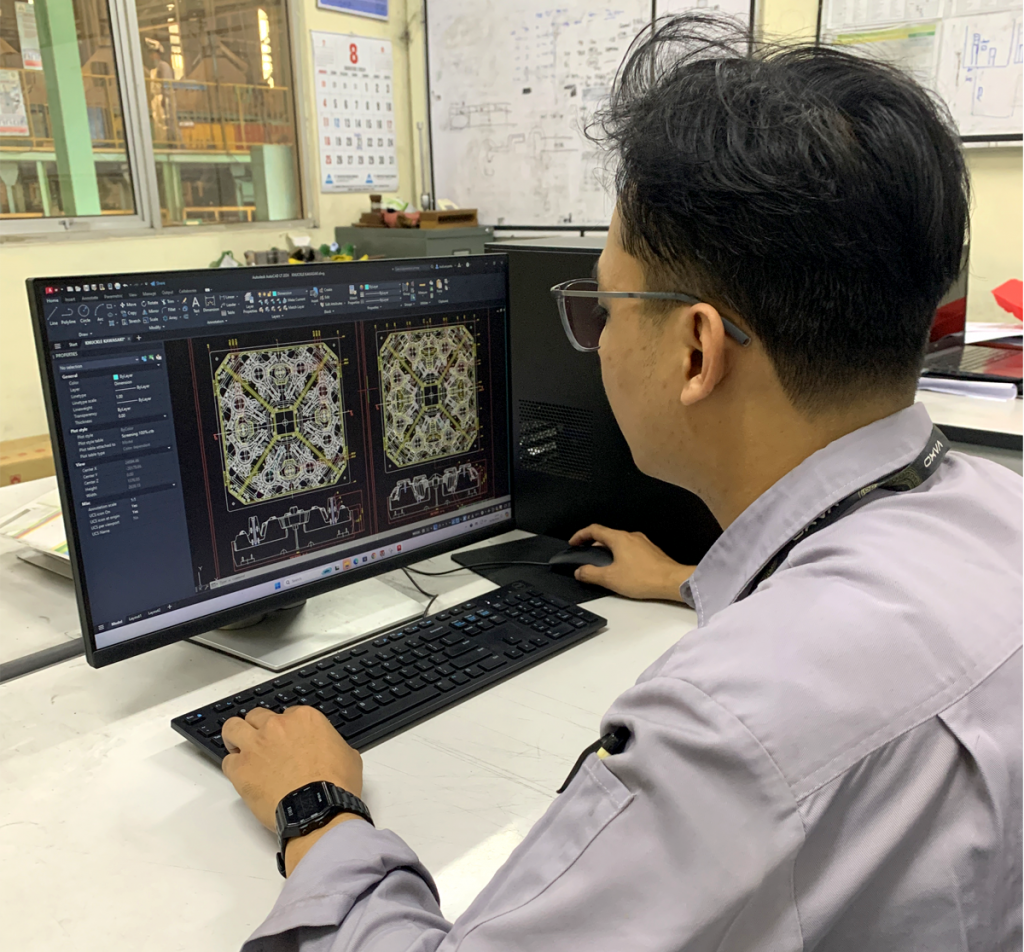

The design of 2D drawings for molds involves creating initial sketches and using CAD software to produce accurate designs. This process ensures that all dimensions and features of the mold are carefully considered before production.

TECHNOLOGICAL ANALYSIS

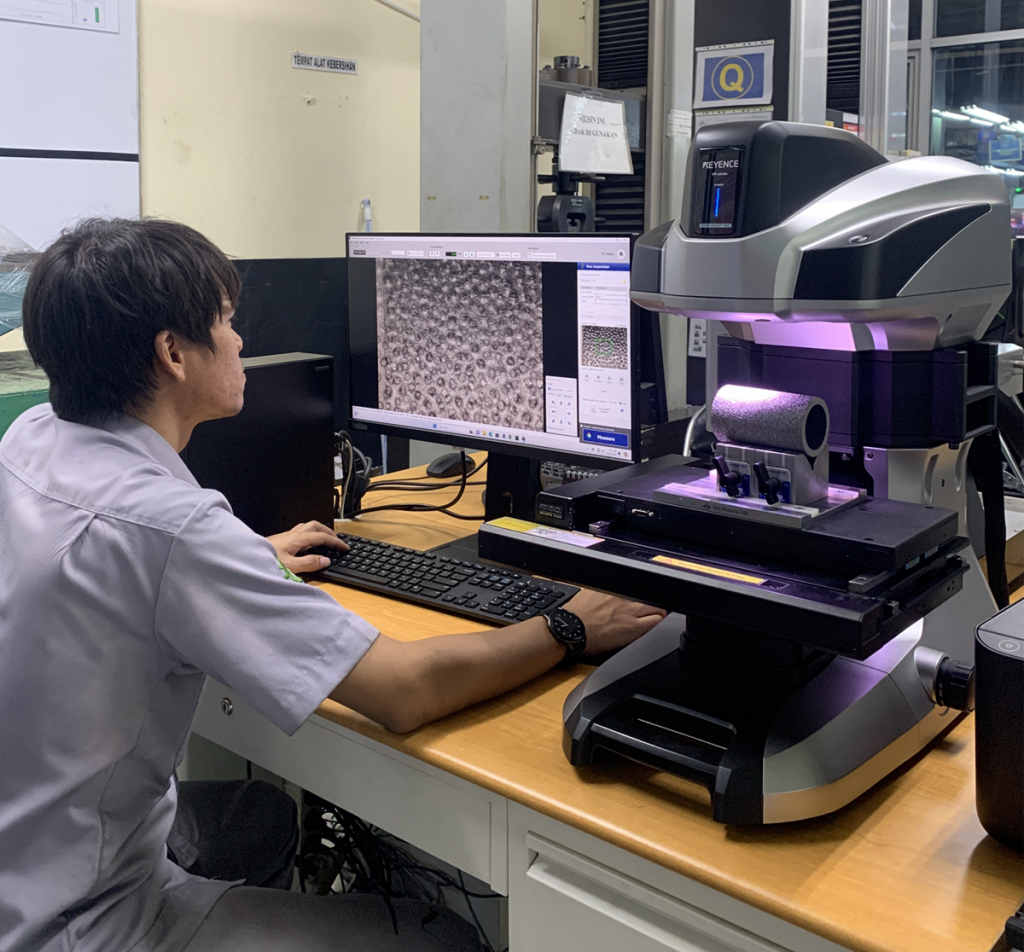

Spectro Machine is used for analyzing material composition with high precision through spectroscopy. This tool is crucial in ensuring material quality before it is used in the production process, particularly in manufacturing and metallurgy industries

The 3D Eye Spyni is an advanced technology used for analyzing the internal structure of castings or iron objects in three dimensions. This technology allows for the precise detection and visualization of any defects or imperfections within the material, thereby supporting the quality of the final product and the efficiency of the production process.